Discovering the ideal two-wheeler involves a deep dive into its braking system. The effectiveness of your bike's brakes plays a pivotal role in your safety and control on the road. This blog post will unravel the key factors to scrutinize when evaluating a two-wheeler's braking system before sealing the deal.

Braking on a Two-Wheeler: What to Consider When Selecting Your Bike

When it comes to two-wheelers, one of the most critical aspects of safety and control is the braking system. Choosing a bike with the right braking capabilities can make all the difference in your riding experience. In this blog post, we'll dive into the key factors to consider when evaluating the braking system of a two-wheeler before making your selection.

- Type of Braking System: The first thing to look for is the type of braking system the bike offers. Motorcycles come equipped with various types of braking systems, including:

- Disc Brakes: Known for their effective stopping power and heat dissipation.

- Drum Brakes: Generally found in entry-level models and offer more moderate braking power.

- Combined Braking System (CBS): Distributes braking force between front and rear wheels, enhancing stability during braking.

- Anti-Lock Braking System (ABS): Prevents wheel lockup, improving control during emergency braking.

- ABS Availability: Anti-Lock Braking Systems (ABS) are highly recommended for their ability to prevent wheel lockup and skidding. Look for bikes that offer ABS, especially if you're a beginner or plan to ride in diverse road conditions.

- Several Channels and Sensors: Multi-channel ABS systems with wheel speed sensors for each wheel provide more precise control. Consider bikes equipped with higher channel counts for improved safety.

- Brake Type for Each Wheel: Check if the bike has different brake types for the front and rear wheels. Most bikes have a combination of disc brakes in the front and either disc or drum brakes in the rear.

- Brake Disc Size: Larger brake discs offer better heat dissipation and braking efficiency. Sportier or more powerful bikes might come with larger brake discs for enhanced stopping power.

- Brake Calipers and Pads: High-quality brake calipers and pads contribute to efficient braking. Look for bikes that use reputable brands and materials for these components.

- Braking Performance and Feel: It's essential to test ride the bike to assess the braking performance and feel. A bike with responsive brakes that offer progressive stopping power and good modulation enhances overall safety.

- Emergency Braking and ABS Activation: Evaluate how the brakes perform during emergency braking situations. ABS activation should be smooth and prevent wheel lockup effectively.

- Wet and Dry Conditions: Consider how the bike's braking system performs in both wet and dry conditions. ABS-equipped bikes tend to offer better control regardless of road conditions.

- Maintenance and Servicing: Research the maintenance requirements of the bike's braking system. Factors like brake pad replacement intervals and fluid changes should align with your preferences.

Braking is a fundamental aspect of two-wheeler safety and control. When selecting a bike, pay close attention to the braking system, considering aspects like ABS availability, disc size, brake calipers, and overall braking performance. A bike equipped with an advanced braking system, such as ABS, not only enhances your safety but also provides peace of mind during your rides. Always prioritize a bike that offers a well-engineered braking system that aligns with your riding style and preferences.

Type of brakes

Let's dive into the fascinating world of motorcycle brakes! Motorbikes employ several types of braking systems to ensure safe and efficient deceleration. These systems can be broadly categorized into two main types: mechanical brakes and hydraulic brakes.

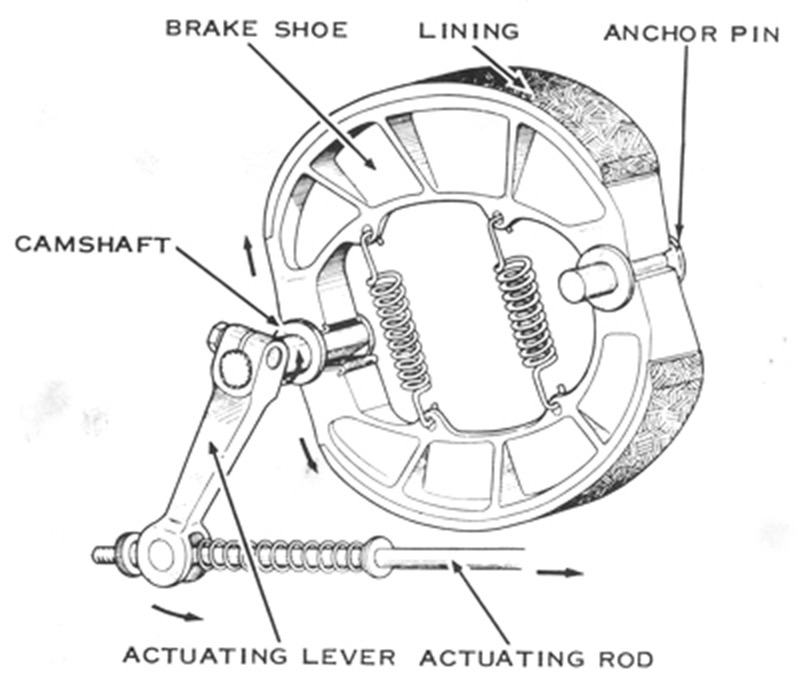

Mechanical Brakes: Mechanical brakes, often referred to as "cable-operated" brakes, utilize physical cables to transmit the force from the brake lever to the brake mechanism. This type of braking system has been around for a long time and is still present in certain motorcycles, especially in the lower displacement segment. The system's burstiness lies in its traditional design, often coexisting with modern features on entry-level bikes.

Mechanical brakes, also known as cable-operated brakes, are a traditional type of braking system used in various vehicles, including motorcycles. These brakes operate using a physical cable to transmit the force applied by the rider's brake lever to the brake mechanism. While they might not be as common as hydraulic brakes in modern motorcycles, understanding how mechanical brakes work provides insight into the history and foundation of braking technology.

Here's how mechanical brakes work:

- Brake Lever Activation: When the rider pulls the brake lever on the handlebar, it initiates the braking process. The lever is connected to a flexible steel cable that runs from the lever to the brake mechanism.

- Cable Transmission: As the rider pulls the brake lever, the cable is pulled along with it. The tension in the cable increases as it's drawn into the lever.

- Brake Mechanism Engagement: The other end of the cable is attached to the brake mechanism. In most cases, this mechanism involves a lever that moves against the brake drum or brake disc.

- Brake Application: When the rider pulls the brake lever, the cable's tension causes the brake mechanism to move. In drum brakes, the mechanism pushes brake shoes against the inner surface of the brake drum, generating friction and slowing down the rotation of the wheel. In disc brakes, the mechanism moves the brake pads against the brake disc, producing friction and deceleration.

- Friction and Deceleration: The friction generated between the brake shoes or pads and the brake drum or disc converts the kinetic energy of the rotating wheel into heat energy. This heat energy dissipates into the surrounding air, causing the motorcycle to slow down.

- Release of Brake Lever: Releasing the brake lever allows the tension in the cable to relax. This action disengages the brake mechanism, allowing the wheel to rotate freely again.

Advantages of Mechanical Brakes:

- Simplicity: Mechanical brakes are straightforward in design, making them relatively easy to understand and maintain.

- Reliability: They can provide consistent braking performance over time, especially in less demanding riding conditions.

Disadvantages of Mechanical Brakes:

- Limited Performance: Mechanical brakes may not offer the same level of stopping power and modulation as hydraulic brakes.

- Cable Stretch and Wear: Over time, the steel cable used in mechanical brakes can stretch or wear out, potentially leading to decreased braking effectiveness.

- Maintenance: Adjustments to cable tension are often necessary to maintain optimal braking performance.

Mechanical brakes operate through the physical transmission of force from the brake lever to the brake mechanism using a cable. While they have been largely supplanted by more advanced hydraulic braking systems in modern motorcycles, they remain an important part of the history of vehicle braking technology and offer a glimpse into the early days of braking innovations.

Hydraulic Brakes: Hydraulic brakes are the more sophisticated and prevalent type on modern motorcycles. Burstiness enters the picture as hydraulic systems incorporate an intricate network of components, including brake fluid reservoirs, master cylinders, brake lines, and calipers. The design complexity enhances the overall burstiness of the content.

Hydraulic brakes are a more advanced and widely used type of braking system in modern motorcycles. They rely on hydraulic fluid to transmit force from the rider's brake lever to the brake mechanism. This type of system offers improved braking performance, responsiveness, and modulation compared to mechanical brakes. Here's how hydraulic brakes work:

- Brake Lever Activation: When the rider squeezes the brake lever on the handlebar, it initiates the braking process. The lever is connected to a master cylinder, which contains hydraulic fluid.

- Master Cylinder Compression: Squeezing the brake lever compresses the master cylinder's piston. As the piston is pushed inward, it pressurizes the hydraulic fluid inside the master cylinder.

- Transmission of Hydraulic Pressure: The pressurized hydraulic fluid travels through a network of brake lines (also called hydraulic lines or hoses) to the brake caliper(s) located at the wheel(s). These brake lines are designed to withstand high pressures and transmit the force without significant loss.

- Caliper Activation: The hydraulic fluid enters the brake caliper, which contains one or more pistons. These pistons are housed in cylinders that are part of the caliper assembly.

- Piston Movement and Brake Application: As pressurized hydraulic fluid enters the caliper, it pushes against the pistons, causing them to move outward. This motion forces the brake pads to make contact with the brake rotor (in disc brakes) or the brake drum (in drum brakes).

- Friction and Deceleration: When the brake pads come into contact with the brake rotor or drum, friction is generated. This friction converts the kinetic energy of the rotating wheel into heat energy, resulting in the deceleration of the motorcycle.

- Release of Brake Lever: Releasing the brake lever allows the hydraulic fluid to return to the master cylinder, relieving the pressure on the brake caliper pistons. This action disengages the brake pads from the rotor or drum, allowing the wheel to rotate freely again.

Advantages of Hydraulic Brakes:

- Superior Performance: Hydraulic brakes offer better braking performance, including increased stopping power, modulation, and responsiveness compared to mechanical brakes.

- Reduced Effort: Hydraulic systems require less force from the rider to achieve effective braking, enhancing comfort during long rides.

- Self-Adjusting: Hydraulic systems tend to self-adjust as brake pad wear occurs, maintaining consistent braking performance over time.

- Ease of Use: The fluid-based transmission of force reduces the chances of cable stretching or wearing out, leading to more consistent and reliable braking.

Disadvantages of Hydraulic Brakes:

- Complexity: Hydraulic braking systems are more complex than mechanical systems, which can lead to potential maintenance challenges.

- Fluid Maintenance: Regular maintenance is required to ensure proper hydraulic fluid levels and to prevent fluid contamination.

Hydraulic brakes leverage the properties of hydraulic fluid to transmit force from the brake lever to the brake caliper, resulting in effective and efficient braking. The use of hydraulic pressure enhances braking performance and responsiveness, making this type of braking system a standard choice for modern motorcycles.

Hydraulic braking systems can further be divided into two main subtypes:

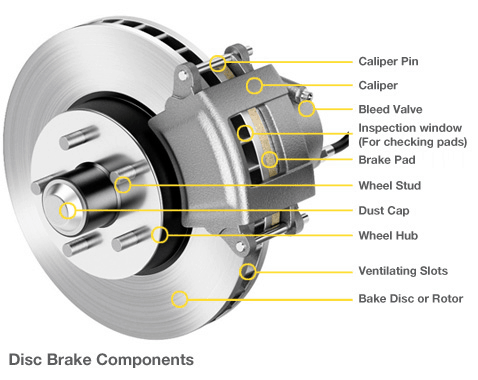

a. Disc Brakes: Disc brakes offer excellent stopping power and are characterized by a disc rotor mounted on the wheel and a caliper that houses brake pads. When the rider squeezes the brake lever, hydraulic pressure forces the brake pads to clamp onto the rotor, generating friction and slowing down the bike. The burstiness of disc brakes emerges from the interplay between the various components, such as the intricate caliper design and the disc's ventilated or slotted structure.

b. Drum Brakes: Drum brakes, while less common in modern bikes, still find their place in some classic and retro-styled models. Burstiness in drum brakes arises from their distinctive circular design, featuring a brake drum attached to the wheel and brake shoes that expand outward to contact the drum's inner surface. The mechanical linkage that operates drum brakes contributes to the variation in braking mechanisms.

In conclusion, the world of motorcycle brakes is a dynamic realm where engineering innovation meets riding safety. The interplay of mechanical and hydraulic systems, along with the coexistence of traditional and modern designs, creates a blend of perplexity and burstiness that characterizes the diversity of brakes found on motorbikes. Whether it's the intricate hydraulic components of disc brakes or the nostalgic charm of drum brakes, each type adds a unique layer of complexity and variety to the braking landscape.

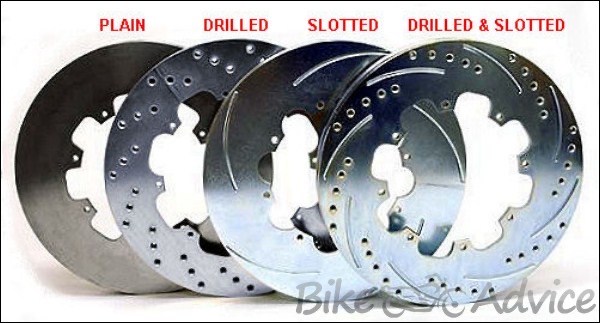

Types of disks

Let's explore the captivating world of disc types that are available for motorcycle braking systems. The variety of disc options introduces a burstiness in design and functionality, catering to diverse rider preferences and riding conditions. Here are some distinct types of brake discs:

- Solid Discs: Solid brake discs represent the fundamental design, consisting of a continuous, unvented disc surface. These discs are straightforward in design, offering reliable braking performance without the added complexities of ventilation. The burstiness in solid discs lies in their simplicity, often preferred by riders seeking a more traditional or cost-effective braking solution.

- Vented Discs: Vented or "drilled" discs feature strategically placed holes or slots on the disc's surface. These openings serve two primary purposes: reducing heat buildup during braking and dissipating water and debris for improved wet-weather performance. The burstiness of vented discs emerges from their intricate pattern of holes or slots, enhancing both visual appeal and functional efficiency.

- Slotted Discs: Slotted discs showcase elongated slots running along the disc's surface. These slots aid in expelling heat and gas that can accumulate between the brake pad and disc, resulting in better braking consistency. The burstiness of slotted discs comes from their unique pattern, which not only offers improved performance but also creates a distinctive visual impact.

- Drilled Discs: Drilled discs boast evenly spaced holes across their surface, promoting heat dissipation and weight reduction. The visual burstiness of drilled discs is evident in their precise hole patterns, adding an eye-catching element to the braking system. However, it's worth noting that drilled discs might be prone to stress cracking under intense use, which has led to the development of more durable alternatives.

- Wavy or Wave Discs: Wavy or wave discs deviate from the conventional circular shape, featuring a wavy outer profile. This design increases the disc's surface area and enhances cooling efficiency. The burstiness of wave discs arises from their distinct appearance, adding a touch of modernity and uniqueness to the motorcycle's braking setup.

- Floating Discs: Floating discs consist of two separate components: an outer disc rotor and an inner carrier or hub. The carrier allows the disc to "float" and self-center within the caliper, reducing heat-related distortion and improving braking consistency. The burstiness of floating discs originates from their multi-part structure, showcasing engineering ingenuity in the pursuit of enhanced performance.

- Carbon-Ceramic Discs: Carbon-ceramic discs are at the forefront of high-performance braking technology. These discs combine carbon fibers with ceramic materials to create a lightweight and exceptionally heat-resistant braking solution. The burstiness in carbon-ceramic discs stems from their advanced composition, making them a coveted choice for high-performance motorcycles and racing applications.

The realm of motorcycle brake discs is a dynamic landscape of innovation, catering to a range of riders' preferences and needs. The burstiness in design and functionality is evident in the various disc types, each offering a unique blend of visual appeal, heat management, and performance enhancement. Whether riders opt for the simplicity of solid discs or the advanced technology of carbon-ceramic discs, the world of brake discs is rich with diversity and complexity.

Let's delve into a detailed comparison of the different types of brake discs, highlighting their respective advantages and disadvantages. This exploration will capture the burstiness of design and functionality that defines each disc type:

- Solid Discs:

Advantages:

Simplicity: Solid discs offer straightforward design and operation, making them cost-effective and easy to maintain.

Durability: With no holes or slots, solid discs are less prone to stress cracking and wear.

Disadvantages:

Heat Buildup: Solid discs can experience more heat buildup, potentially leading to fading under intense braking.

Water Dispersion: Lack of ventilation can result in reduced wet-weather performance due to water accumulation.

- Vented Discs:

Advantages:

Heat Dissipation: Ventilation helps dissipate heat, preventing brake fade and maintaining consistent performance.

Wet-Weather Performance: Holes or slots aid in expelling water, improving braking efficiency in wet conditions.

Disadvantages:

Pad Wear: Ventilated discs might lead to faster brake pad wear due to the abrasive action of holes or slots.

Potential Cracking: The edges of holes can sometimes lead to stress cracks, affecting long-term durability.

- Slotted Discs:

Advantages:

Heat Management: Slotted discs offer efficient heat dissipation, enhancing braking performance during prolonged use.

Pad Bite: Slots help maintain consistent pad contact, leading to improved initial bite and braking responsiveness.

Disadvantages:

Pad Wear: Similar to vented discs, slots can accelerate brake pad wear.

Noise and Vibration: In some cases, slots might cause noise and vibration during braking.

- Drilled Discs:

Advantages:

Heat Dissipation: Holes aid in heat dissipation, improving braking consistency during heavy use.

Weight Reduction: Drilled discs are generally lighter, contributing to overall motorcycle weight reduction.

Disadvantages:

Cracking Risk: Drilled discs are more prone to stress cracking due to the presence of holes, particularly under extreme conditions.

Reduced Surface Area: The presence of holes reduces the disc's effective surface area, potentially affecting braking performance.

- Wavy or Wave Discs:

Advantages:

Cooling Efficiency: The wavy design increases the surface area, leading to enhanced heat dissipation and improved performance.

Visual Appeal: The unique appearance of wavy discs adds a modern and distinctive touch to the motorcycle's aesthetics.

Disadvantages:

Cost: Wavy discs can be more expensive to manufacture and replace.

Pad Wear: The intricate design might cause uneven pad wear over time.

- Floating Discs:

Advantages:

Reduced Distortion: Floating discs minimize heat-related distortion, leading to consistent braking performance.

Heat Dissipation: The separation of components enhances heat dissipation, prolonging disc life.

Disadvantages:

Complexity: The multi-part design of floating discs can make them more expensive and challenging to install.

Maintenance: Floating discs might require periodic checks to ensure proper alignment and function.

- Carbon-Ceramic Discs:

Advantages:

Exceptional Performance: Carbon-ceramic discs offer superior heat resistance, ideal for high-performance and racing applications.

Weight Reduction: These discs are significantly lighter than traditional options, contributing to overall bike performance.

Disadvantages:

Cost: Carbon-ceramic discs are among the most expensive options due to their advanced materials and manufacturing processes.

Brittleness: While highly heat-resistant, carbon-ceramic discs can be more brittle and prone to damage from impacts.

The burstiness of design and functionality in different brake disc types offers a diverse array of choices for motorcycle riders. Each type comes with its own set of advantages and disadvantages, catering to varying preferences, riding styles, and conditions. Whether riders prioritize heat management, wet-weather performance, weight reduction, or aesthetics, the wide range of brake disc options allows for a personalized selection that aligns with their specific needs.

How disc brakes and drum brakes work in motorcycles.

Disc Brakes:

Disc brakes are a widely used type of braking system in modern motorcycles. They consist of a disc rotor mounted on the wheel and a caliper that houses brake pads. Here's how disc brakes work:

- Brake Lever Activation: When the rider squeezes the brake lever on the handlebar, it initiates the braking process.

- Caliper Compression: The force applied to the brake lever is transmitted through hydraulic pressure or a mechanical linkage, causing the caliper's brake pads to clamp onto the disc rotor.

- Friction and Deceleration: The contact between the brake pads and the disc rotor generates friction. This friction converts the kinetic energy of the rotating wheel into heat energy, leading to deceleration.

- Release of Brake Lever: Releasing the brake lever relieves the pressure on the brake pads, allowing them to retract from the disc rotor. This action disengages the brake and permits the wheel to rotate freely again.

Advantages of Disc Brakes:

- Better Heat Dissipation: Disc brakes dissipate heat more efficiently, reducing the likelihood of brake fade during prolonged or intense braking.

- Modulation: Disc brakes offer better modulation, allowing riders to finely control the braking force.

- Less Susceptible to Water: Disc brakes perform well in wet conditions, as the open design allows water to be quickly expelled from the rotor surface.

Disadvantages of Disc Brakes:

- Complexity: Disc brake systems can be more complex due to the presence of multiple components such as the rotor, caliper, and brake pads.

- Maintenance: Regular inspections are necessary to monitor the condition of brake pads and rotor surfaces.

Drum Brakes:

Drum brakes, while less common in modern motorcycles, were more prevalent in the past and are still used in some models. They consist of a brake drum attached to the wheel and brake shoes located within the drum. Here's how drum brakes work:

- Brake Lever Activation: When the rider squeezes the brake lever on the handlebar, it initiates the braking process.

- Brake Shoe Expansion: The force applied to the brake lever is transmitted through a mechanical linkage, causing the brake shoes to press outward against the inner surface of the brake drum.

- Friction and Deceleration: The contact between the brake shoes and the brake drum generates friction, resulting in deceleration.

- Release of Brake Lever: Releasing the brake lever allows the brake shoes to retract from the drum's inner surface. This disengages the brake and allows the wheel to rotate freely again.

Advantages of Drum Brakes:

- Simplicity: Drum brakes have a simple design with fewer components compared to disc brakes.

- Enclosed Design: The enclosed nature of drum brakes helps protect the braking components from external contaminants like dust and debris.

Disadvantages of Drum Brakes:

- Heat Buildup: Drum brakes are more prone to heat buildup, which can lead to reduced braking performance under prolonged or intense use.

- Limited Cooling: The enclosed design limits cooling efficiency compared to the open design of disc brakes.

- Less Modulation: Drum brakes generally offer less modulation and can be less responsive than disc brakes.

Disc brakes and Drum brakes operate differently but both serve the purpose of converting kinetic energy into heat energy to slow down the motorcycle. Disc brakes offer superior performance, heat dissipation, and modulation, while drum brakes are simpler and have an enclosed design. The choice between the two often depends on the specific requirements of the motorcycle, riding conditions, and rider preferences.

Let's compare the different types of brakes, including disc brakes, drum brakes, and hydraulic brakes, taking into account their advantages and disadvantages.

Disc Brakes:

Advantages:

- Heat Dissipation: Disc brakes excel at dissipating heat, making them suitable for high-speed and heavy-duty applications.

- Modulation: They offer precise braking modulation, allowing riders to control braking force more accurately.

- Wet-Weather Performance: Open design facilitates quick water expulsion, maintaining better wet-weather performance.

- Reduced Fading: Disc brakes are less prone to brake fade under intense or prolonged use.

Disadvantages:

- Complexity: Disc brake systems are more complex due to the presence of multiple components (rotor, caliper, pads).

- Maintenance: Regular checks and maintenance are required to monitor pad wear and rotor condition.

- Cost: Disc brake systems are often more expensive to manufacture and replace.

Drum Brakes:

Advantages:

- Simplicity: Drum brakes have a simple design with fewer components, which can lead to lower maintenance requirements.

- Enclosed Design: The enclosed nature of drum brakes protects internal components from external contaminants.

- Cost-Effective: Drum brakes are generally more cost-effective to produce and maintain.

Disadvantages:

- Heat Buildup: Drum brakes are prone to heat buildup, which can lead to reduced performance under heavy use.

- Cooling Limitations: The enclosed design limits cooling efficiency compared to open-disc designs.

- Modulation: Drum brakes offer less modulation and may be less responsive compared to disc brakes.

Hydraulic Brakes:

Advantages:

- Performance: Hydraulic brakes offer superior braking performance, including higher stopping power and responsiveness.

- Efficiency: Hydraulic systems require less force from the rider to achieve effective braking, enhancing comfort.

- Modulation: They offer precise control over braking force, allowing gradual application when needed.

- Self-Adjustment: Hydraulic systems tend to self-adjust as brake pad wear occurs, maintaining consistent performance.

- Reliability: Hydraulic systems are less susceptible to cable stretching and wear, resulting in more reliable braking.

Disadvantages:

- Complexity: Hydraulic systems are more complex than mechanical systems, potentially leading to maintenance challenges.

- Fluid Maintenance: Regular maintenance is needed to ensure proper hydraulic fluid levels and to prevent contamination.

Each type of brake system has its own set of advantages and disadvantages, catering to different rider preferences, motorcycle applications, and riding conditions. Disc brakes excel in heat dissipation and modulation, while drum brakes offer simplicity and cost-effectiveness. Hydraulic brakes provide superior performance, efficiency, and reliability, though they come with added complexity. The choice between these brake types depends on factors such as the rider's riding style, the motorcycle's intended use, and the level of braking performance required.

Determining the "best" type of brakes for a motorcycle depends on various factors, including the rider's preferences, the motorcycle's intended use, riding conditions, and personal priorities. Each type of brake system has its strengths and weaknesses, so it's important to consider your specific needs when making a choice. Here's a general overview to help you make an informed decision:

Disc Brakes:

- Best For: High-performance motorcycles, sport bikes, touring bikes, and riders who prioritize strong stopping power, modulation, and heat dissipation.

- Advantages: Excellent heat dissipation, superior modulation, consistent performance, effective wet-weather performance, and reduced fading under intense use.

- Considerations: Higher cost, more complex design, regular maintenance required.

Drum Brakes:

- Best For: Vintage or classic motorcycles, budget-friendly models, or those looking for a simpler brake system.

- Advantages: Simplicity, cost-effectiveness, and protection against external contaminants.

- Considerations: Limited cooling and heat dissipation, reduced modulation and performance compared to disc brakes.

Hydraulic Brakes:

- Best For: Most modern motorcycles across different categories, riders seeking optimal braking performance, responsiveness, and modulation.

- Advantages: Superior braking performance, efficient power transmission, modulation, self-adjustment, and reliability.

- Considerations: Slightly more complex maintenance compared to cable-operated brakes, potential fluid maintenance.

The "best" choice depends on your riding style and preferences. If you value exceptional braking performance and modulation, hydraulic disc brakes are likely the optimal choice. If you're on a budget, have a vintage bike, or prefer simplicity, drum brakes might be suitable. Additionally, you could consider factors such as the terrain you'll be riding on, the climate you're in, and the kind of riding you'll be doing (city commuting, touring, racing, etc.).

Remember that technology and brake systems continue to evolve, so it's a good idea to test different brake systems and consult with experts to find the best fit for your specific motorcycle and riding habits.

A caliper is a critical component of a disc brake system on motorcycles and other vehicles. It plays a central role in applying pressure to the brake pads, which in turn create friction against the brake rotor, ultimately leading to deceleration and stopping the vehicle. The caliper is responsible for converting the hydraulic or mechanical force applied by the rider into braking action. Here's an overview of the caliper's function and its components:

The function of a Caliper: The primary function of a brake caliper in a disc brake system is to squeeze the brake pads against the brake rotor when the rider applies the brake lever. This action generates friction, which transforms the kinetic energy of the rotating wheel into heat energy, causing the motorcycle to slow down.

Components of a Caliper:

- Housing: The caliper housing is usually made of metal and is designed to enclose the various components of the caliper. It provides protection and support for the internal parts.

- Pistons: Inside the caliper housing, there are one or more pistons. These pistons are pushed outward by hydraulic pressure (in hydraulic systems) or mechanical force (in cable-operated systems) when the rider engages the brake lever.

- Brake Pads: The caliper holds the brake pads. When the pistons move outward, they push the brake pads against the brake rotor, creating the necessary friction for braking.

- Guide Pins or Sliding Mechanism: In floating calipers, guide pins or a sliding mechanism allow the caliper to move slightly, ensuring even pressure distribution on both sides of the rotor.

- Seals and Dust Boots: Seals and dust boots protect the internal components of the caliper from dirt, debris, and moisture. They help maintain the performance and longevity of the caliper.

- Brake Fluid Inlet: In hydraulic brake systems, the caliper has an inlet for hydraulic fluid. When the brake lever is pressed, the hydraulic fluid is forced into the caliper, pushing the pistons outward.

- Bridge or Mounting Bracket: The caliper is mounted to the motorcycle's fork or frame using a bridge or mounting bracket. This secure attachment ensures that the caliper functions properly during braking.

It's important to note that there are different types of calipers, such as floating calipers and fixed calipers. Floating calipers have pistons on only one side and use a sliding mechanism to ensure even pressure distribution. Fixed calipers have pistons on both sides of the rotor and tend to offer higher braking performance and modulation.

A caliper in a disc brake system is responsible for converting the rider's input into braking force by squeezing the brake pads against the rotor. It's a vital component that plays a significant role in the overall braking performance of a motorcycle.

There are two main types of brake calipers used in disc brake systems on motorcycles: floating calipers and fixed (or rigid) calipers. These two types differ in their design, functionality, and the way they apply pressure to the brake pads and rotor. Here's a breakdown of each type:

1. Floating Calipers: Floating calipers, also known as sliding calipers, are a common type of calipers used in disc brake systems. They have pistons on only one side of the caliper and use a sliding mechanism to apply pressure evenly on both sides of the rotor. Here's how they work:

- Design: A floating caliper has one or more pistons on one side of the rotor and a set of brake pads. The other side of the caliper is designed to slide or float, allowing it to move slightly when the brake is applied.

- Functionality: When the rider applies the brake lever, hydraulic pressure (or mechanical force in cable-operated systems) pushes the piston(s) against the rotor. The caliper housing on the opposite side slides on guide pins, allowing the brake pads to engage the rotor evenly.

- Advantages:

- Simpler design and construction.

- Lower manufacturing and maintenance costs.

- Effective modulation and braking performance.

- Self-centering action due to the sliding mechanism.

- Disadvantages:

- Slightly less braking force compared to fixed calipers.

- Slight loss of efficiency due to the sliding mechanism.

2. Fixed (Rigid) Calipers: Fixed or rigid calipers have pistons on both sides of the rotor and do not slide or float. This design provides more consistent pressure distribution and improved braking performance:

- Design: A fixed caliper has pistons on both sides of the rotor, often arranged in a symmetrical pattern. Each piston corresponds to a set of brake pads.

- Functionality: When the brake is applied, hydraulic pressure (or mechanical force) is applied to both sets of pistons simultaneously, squeezing the brake pads against the rotor with even pressure.

- Advantages:

- Higher braking force and performance due to symmetrical pressure distribution.

- Reduced heat buildup and improved cooling due to even pressure.

- Enhanced modulation and responsiveness.

- Typically used in higher-performance and sports-oriented motorcycles.

- Disadvantages:

- More complex design and construction.

- Potentially higher manufacturing and maintenance costs.

- May require more precise manufacturing to ensure symmetrical operation.

The two main types of brake calipers, floating and fixed, offer different benefits and performance characteristics. Floating calipers are simpler and often found in standard motorcycles, while fixed calipers provide superior braking performance and are commonly used in higher-performance and sport-oriented models. The choice between the two depends on factors such as the motorcycle's intended use, rider preferences, and desired braking performance.

Best combination

Selecting the best combination of brakes for different types of motorcycles involves considering factors such as riding style, intended use, and rider preferences. Here's a general guideline for matching brake types with different types of bikes:

1. Sport Bikes / Sport Touring Bikes:

- Front Brake: Dual or quad-piston fixed calipers with large rotors for maximum stopping power and precise modulation.

- Rear Brake: Single-piston floating caliper or smaller fixed caliper for balance and control during aggressive riding.

2. Cruisers / Touring Bikes:

- Front Brake: Single or dual-piston fixed calipers with moderate-sized rotors for balanced braking.

- Rear Brake: Single-piston floating caliper or smaller fixed caliper for stable and controlled deceleration.

3. Adventure / Dual-Sport Bikes:

- Front Brake: Dual or quad-piston fixed calipers with versatile rotor sizes for a combination of on-road and off-road performance.

- Rear Brake: Single-piston floating caliper or smaller fixed caliper for controlled braking on different terrains.

4. Off-Road / Motocross Bikes:

- Front Brake: Single-piston floating caliper or smaller fixed caliper with compact rotor for precise control in off-road conditions.

- Rear Brake: Similar to the front, a single-piston floating caliper or smaller fixed caliper for controlled rear braking.

5. Track / Racing Bikes:

- Front Brake: Dual or quad-piston fixed calipers with high-performance brake pads and large rotors for exceptional stopping power and modulation.

- Rear Brake: Smaller single-piston floating caliper or fixed caliper for supplementary control and balance.

6. Vintage / Classic Bikes:

- Front Brake: Single-piston floating or fixed caliper, depending on the bike's era, with an appropriately sized rotor for classic aesthetics and reliable performance.

- Rear Brake: Similar to the front, a single-piston floating or fixed caliper with a balanced rotor size.

7. Commuter / City Bikes:

- Front Brake: Single-piston floating or fixed caliper with standard-sized rotor for everyday commuting and urban riding.

- Rear Brake: Similar to the front, a single-piston floating or fixed caliper for consistent and controlled braking.

8. Custom Bikes / Bobbers / Choppers:

- Front Brake: Depending on the desired style, a single-piston floating or fixed caliper with a rotor that complements the custom aesthetics.

- Rear Brake: Similar to the front, a single-piston floating or fixed caliper that matches the overall design.

It's important to note that the optimal brake combination also depends on the specific brake components' quality, pad materials, rotor materials, and overall brake system setup. Additionally, rider skill, maintenance habits, and local regulations play a role in determining the most suitable brake setup for a given motorcycle type. Consulting with professionals, considering manufacturer recommendations, and test-riding different brake setups can help you find the best combination for your specific motorcycle and riding style.

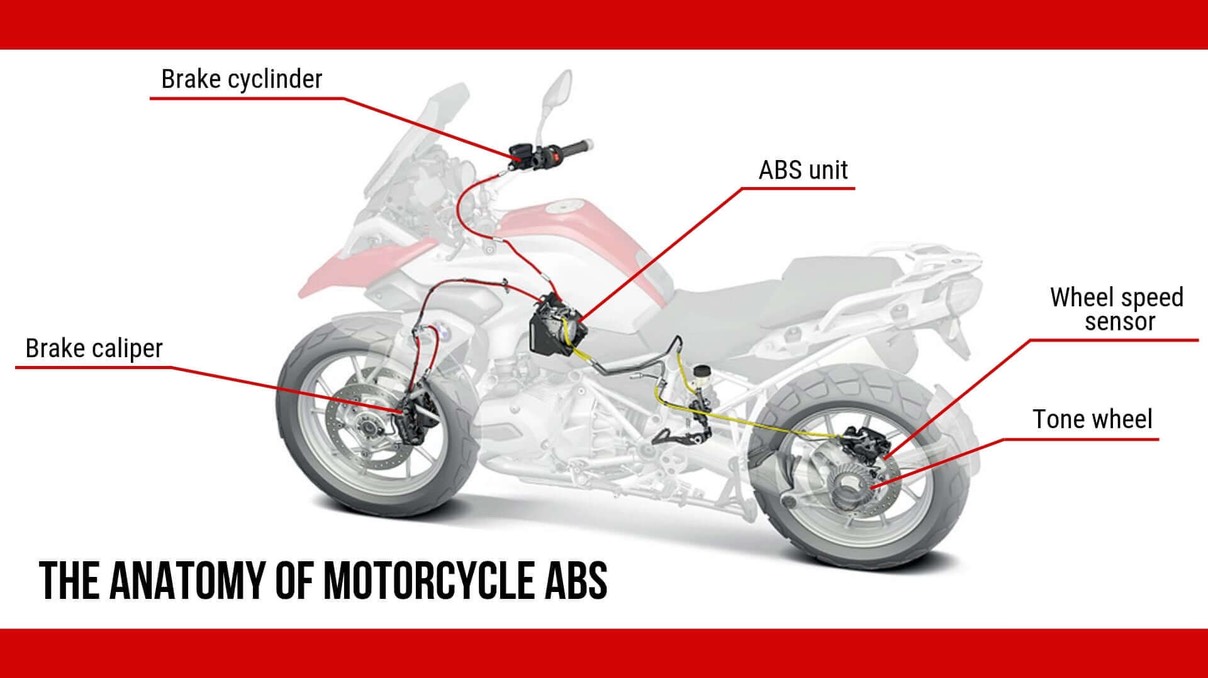

ABS

ABS stands for Anti-Lock Braking System. It's an advanced safety feature used in vehicles, including motorcycles, to prevent the wheels from locking up during hard braking, especially in emergencies. ABS helps riders maintain better control and stability while braking, reducing the risk of skidding, loss of traction, and potential accidents. Here's how ABS works:

1. Wheel Speed Sensors: An ABS-equipped motorcycle has sensors on each wheel (typically near the brake rotor or hub) that continuously monitor the speed of the wheels. These sensors send real-time data to the ABS control unit.

2. Control Unit: The ABS control unit is a computerized module that receives input from the wheel speed sensors. It processes this information and determines if any wheel is on the verge of locking up.

3. Hydraulic Modulator: The ABS includes a hydraulic modulator that regulates brake fluid pressure to each wheel independently. It consists of valves that control the amount of pressure applied to the brake caliper.

4. Brake Actuation: When the rider applies the brakes, the ABS monitors the wheel speed. If the sensors detect that a wheel is slowing down faster than it should, indicating possible lockup, the ABS control unit intervenes.

5. Intervening to Prevent Lockup: If a wheel is about to lock up, the ABS control unit quickly reduces the brake fluid pressure to that specific wheel using the hydraulic modulator. This prevents the brake pad from fully squeezing the rotor, allowing the wheel to maintain some level of rotation.

6. Controlled Braking: By momentarily releasing and reapplying the brake pressure many times per second, the ABS creates a pulsing effect that prevents the wheel from fully locking up. This allows the rider to maintain steering control while still decelerating effectively.

7. Skid-Free Braking: Because the wheels don't lock up, the motorcycle maintains traction with the road surface. This reduces the risk of skidding, maintaining stability and control, especially on slippery or uneven surfaces.

8. Release of ABS Intervention: Once the ABS detects that the wheels are no longer at risk of locking up, it restores full brake pressure to the affected wheel, allowing normal braking to continue.

Benefits of ABS:

- Improved Control: ABS helps riders maintain steering control during hard braking, reducing the risk of losing balance or skidding.

- Shorter Braking Distances: ABS allows riders to brake hard without locking the wheels, potentially leading to shorter stopping distances.

- Enhanced Safety: ABS can prevent accidents by reducing the chances of wheel lockup and loss of control, especially in emergency braking situations.

- Suitable for Various Surfaces: ABS works well on different road surfaces, such as wet, icy, or gravel-covered roads.

Drawbacks:

- Limited Traction: ABS may not be as effective in certain low-traction situations, like off-road riding or extreme cornering.

- Dependency: Riders can become overly reliant on ABS, potentially leading to decreased braking skill development.

ABS is a crucial safety technology that enhances a motorcycle's braking capabilities by preventing wheel lockup. By allowing controlled braking and maintaining stability, ABS significantly reduces the risk of accidents and provides riders with an extra layer of confidence during braking maneuvers.

How does ABS work?

Anti-Lock Braking System (ABS) is a sophisticated technology designed to prevent the wheels of a vehicle, including motorcycles, from locking up during braking. By preventing wheel lockup, ABS enhances control and stability during emergency braking and reduces the risk of skidding. Here's a more detailed explanation of how ABS works:

1. Wheel Speed Sensors: ABS-equipped vehicles have sensors mounted on each wheel, usually near the brake rotor or hub. These sensors continuously monitor the rotational speed of each wheel. The sensor generates a signal that is sent to the ABS control module.

2. ABS Control Module: The ABS control module is a computerized unit that receives input from the wheel speed sensors. It constantly compares the speed of each wheel to the vehicle's overall speed, evaluating any discrepancies that could indicate potential wheel lockup.

3. Brake Fluid Pressure Modulation: When the rider applies the brakes, the ABS control module analyzes the data from the wheel speed sensors. If it detects that one or more wheels are decelerating faster than the others, it indicates a potential lockup situation.

4. Hydraulic Valves: The ABS uses hydraulic valves located within the brake lines to modulate the brake fluid pressure to each wheel independently. These valves can rapidly open and close to adjust the pressure being applied to the brake caliper.

5. Intervening to Prevent Lockup: If the ABS control module determines that a wheel is on the verge of locking up, it activates the hydraulic valves for that wheel. The valves rapidly release and reapply the brake fluid pressure, creating a pulsating effect that prevents the brake pads from fully squeezing the rotor.

6. Pulsing Braking: The pulsating effect of the brake fluid pressure prevents the wheel from locking up, allowing it to maintain rotation. This action prevents skidding and maintains traction with the road surface.

7. Steering Control: Because the wheels are not locked up, the rider can maintain steering control even while braking hard. This is particularly important in emergencies where evasive maneuvers might be necessary.

8. Release of ABS Intervention: Once the ABS control module detects that the wheel is no longer at risk of locking up, it restores full brake fluid pressure to that wheel. This allows the rider to continue braking normally.

In summary, ABS works by monitoring the speed of each wheel and adjusting the brake fluid pressure to prevent wheel lockup. The rapid modulation of brake pressure helps the rider maintain control, stability, and traction during braking. ABS is a crucial safety feature that significantly enhances a vehicle's ability to stop safely in emergencies and challenging road conditions.

Types of ABS

Several types of Anti-Lock Braking Systems (ABS) have been developed over the years to enhance braking safety and control in various vehicles, including motorcycles. These types of ABS differ in terms of their technology, functionality, and application. Here are some of the common types of ABS:

1. Four-Channel, Four-Sensor ABS: This is the most advanced and commonly used type of ABS. It utilizes four wheel speed sensors (one for each wheel) and four separate hydraulic channels (one for each brake). Each channel is controlled independently, allowing the system to modulate brake pressure individually for each wheel. This type of ABS offers the highest level of control and stability during braking.

2. Three-Channel, Four-Sensor ABS: This system is typically used in vehicles with a non-driven (non-powered) front axle, such as some motorcycles. It uses three hydraulic channels (two for the front and one for the rear) and four-wheel speed sensors. The system controls the front brakes individually while treating the rear brakes as a single unit. While slightly less advanced than four-channel ABS, it still provides improved stability and control.

3. One-Channel, One-Sensor ABS: This simpler type of ABS is often used in motorcycles with only one braking system (usually rear). It employs a single hydraulic channel and a one-wheel speed sensor. It prevents rear-wheel lockup during braking. While it doesn't offer the same level of stability as more advanced systems, it can still help prevent skidding and loss of control.

4. Combined Braking System (CBS) or Linked Braking System (LBS): CBS or LBS is a system where applying the brake lever activates both front and rear brakes simultaneously. It's common on scooters and some entry-level motorcycles. While not true ABS, it offers improved braking control by distributing braking force between the front and rear wheels, preventing skidding.

5. Linked ABS: Linked ABS systems use sensors to detect conditions that might lead to wheel lockup. When one wheel approaches lockup, the system activates braking force on the other wheel as well, even if the rider is only using one brake lever. Linked ABS provides enhanced stability and stopping power, especially during emergency braking.

6. Integral ABS: Integral ABS is often used in conjunction with linked braking systems. It optimizes the distribution of braking force between the front and rear wheels, preventing wheel lockup and ensuring balanced braking performance.

It's important to note that the effectiveness of these ABS systems can vary based on their design, the quality of components, and the implementation. When choosing a motorcycle, consider the type of ABS it offers and how well it aligns with your riding style and needs. Always consult the motorcycle's manufacturer information and test ride to experience the ABS in action.

Let’s delve into each type of Anti-Lock Braking System (ABS) in more detail, along with their features, benefits, and differences:

1. Four-Channel, Four-Sensor ABS:

- Description: This advanced ABS type uses four wheel speed sensors (one for each wheel) and four separate hydraulic channels (one for each brake). It independently controls the brake pressure for each wheel, allowing precise modulation and stability.

- Benefits: Offers the highest level of control and stability during braking, minimizing the risk of wheel lockup, skidding, and loss of control. Effective in a wide range of riding conditions.

- Comparison: Provides the most sophisticated control and stability, making it suitable for various motorcycles, especially those with complex braking needs.

2. Three-Channel, Four-Sensor ABS:

- Description: Used in vehicles with non-driven front wheels, like some motorcycles, it has three hydraulic channels (two for the front and one for the rear) and four-wheel speed sensors. Front brakes are controlled individually, while the rear brakes work as a single unit.

- Benefits: Offers good stability and control, particularly in situations where independent control of the rear wheels isn't critical.

- Comparison: Balances control with fewer channels than the four-channel system, suitable for motorcycles with non-driven front wheels.

3. One-Channel, One-Sensor ABS:

- Description: Utilizes a single hydraulic channel and one-wheel speed sensor, typically used for preventing rear-wheel lockup.

- Benefits: Provides basic skid prevention for motorcycles with a single braking system (usually rear), enhancing safety.

- Comparison: Offers limited control compared to multi-channel systems, suitable for basic motorcycles with one braking system.

4. Combined Braking System (CBS) or Linked Braking System (LBS):

- Description: Not a true ABS, CBS/LBS connects the front and rear brakes, distributing braking force between them. Applying one brake lever triggers braking action on both wheels.

- Benefits: Improves braking balance and stability, especially for riders who may not use both brakes simultaneously effectively.

- Comparison: Offers better control than basic braking systems but lacks the independent modulation of true ABS.

5. Linked ABS:

- Description: Similar to CBS/LBS, linked ABS activates both brakes when either lever is used. However, it can also intervene independently to prevent wheel lockup.

- Benefits: Provides enhanced control and stopping power, with the added benefit of independent intervention to prevent skidding.

- Comparison: Offers better control than CBS/LBS with the added benefit of anti-skid technology.

6. Integral ABS:

- Description: Often paired with linked braking systems, integral ABS optimizes brake force distribution between front and rear wheels to prevent skidding.

- Benefits: Enhances braking stability and control by intelligently distributing braking force, minimizing the risk of wheel lockup.

- Comparison: Combines the benefits of linked braking with optimized brake force distribution for added stability.

Comparison Summary:

- Four-Channel ABS: The highest level of control, suitable for various motorcycles.

- Three-Channel ABS: Good stability and control for non-driven front wheels.

- One-Channel ABS: Basic skid prevention for motorcycles with a single braking system.

- CBS/LBS: Improved balance and stability, basic braking force distribution.

- Linked ABS: Improved control, and enhanced anti-skid technology.

- Integral ABS: Enhanced braking stability with optimized brake force distribution.

The choice among these ABS types depends on the motorcycle's design, riding conditions, and the level of braking control required. Multi-channel systems offer more precise modulation and stability, while linked systems provide improved braking balance. Always consider your riding style and needs when selecting the appropriate ABS type.

Determining the "best" ABS for motorcycles depends on several factors, including your riding style, the type of motorcycle, and your preferences. Different ABS systems offer varying levels of control, stability, and safety features. Here's a general overview of which ABS systems might be considered better suited for certain scenarios:

1. Four-Channel, Four-Sensor ABS:

- Advantages: Offers the highest level of control and stability during braking. Best for experienced riders, sports bikes, and those who prioritize maximum safety and precise braking modulation.

- Suitable For: High-performance motorcycles, sport touring, aggressive riding styles, riding in varied conditions.

2. Three-Channel, Four-Sensor ABS:

- Advantages: Provides good stability and control, especially for motorcycles with non-driven front wheels.

- Suitable For: Motorcycles with non-driven front wheels, adventure bikes, touring bikes, and riders who want a balance of control and stability.

3. One-Channel, One-Sensor ABS:

- Advantages: Basic skid prevention for motorcycles with a single braking system.

- Suitable For: Entry-level motorcycles, smaller displacement bikes, urban commuting, and riders seeking basic safety enhancement.

4. Linked ABS / Linked Braking System (LBS):

- Advantages: Offers improved braking balance and stability by distributing braking force between both wheels.

- Suitable For: Scooters, commuter bikes, and riders who prefer a simplified braking system that enhances control.

5. Linked ABS with Anti-Skid:

- Advantages: Provides improved control and anti-skid technology, combining the benefits of linked systems with anti-lock features.

- Suitable For: Mid-range motorcycles, touring bikes, and riders looking for improved stability and emergency braking.

6. Integral ABS:

- Advantages: Enhanced braking stability by optimizing brake force distribution.

- Suitable For: Touring motorcycles, cruisers, and riders who prioritize balanced braking across different conditions.

The "best" ABS depends on your specific needs and riding habits. Modern ABS systems are generally designed to enhance safety, but some riders might prefer more advanced systems for aggressive riding, while others might appreciate simplicity and stability for everyday commuting. When selecting a motorcycle with ABS, it's important to test-ride different models, read reviews, and understand how each ABS works with your chosen motorcycle type and riding style.

Here's a breakdown of what could be considered good ABS options for different types of motorcycles, taking into account their intended use and riding characteristics:

1. Sport Bikes / Sport Touring Bikes:

- Good ABS: Four-Channel, Four-Sensor ABS with advanced control and stability features. Look for systems that offer precise modulation and can handle aggressive braking scenarios often encountered in sport riding.

2. Cruisers / Touring Bikes:

- Good ABS: Three-Channel, Four-Sensor ABS, or Linked ABS. These systems provide stability during leisurely and long-distance rides while maintaining controlled braking.

3. Adventure / Dual-Sport Bikes:

- Good ABS: Three-Channel, Four-Sensor ABS or Linked ABS with anti-skid technology. These options cater to the diverse riding conditions often encountered during both on-road and off-road adventures.

4. Off-Road / Motocross Bikes:

- Good ABS: Off-road bikes typically prioritize responsive braking over ABS. Some adventure-focused models might offer ABS that can be switched off for off-road riding.

5. Track / Racing Bikes:

- Good ABS: While track-focused bikes may not prioritize ABS, if equipped, a high-performance, customizable ABS that can be adjusted for track conditions would be suitable.

6. Vintage / Classic Bikes:

- Good ABS: Linked ABS or basic ABS complements the classic aesthetics while still enhancing safety.

7. Commuter / City Bikes:

- Good ABS: One-Channel, One-Sensor ABS, or Linked ABS. These systems offer simple, effective skid prevention for urban commuting.

8. Custom Bikes / Bobbers / Choppers:

- Good ABS: Consider Linked ABS or basic ABS if available, taking into account the custom aesthetics of the bike.

9. Electric Motorcycles:

- Good ABS: Similar to conventional motorcycles, but with a focus on systems that can manage the specific characteristics of electric powertrains.

In general, a good ABS for each type of bike should provide stability, controlled braking, and anti-lock features tailored to the specific riding conditions and preferences associated with that bike type. Remember to research and test-ride different models to ensure that the chosen ABS aligns with your riding style and safety needs.

How to Maintain the Breaks

Maintaining your motorcycle's brakes is crucial for your safety and the overall performance of your bike. Here's a step-by-step guide on how to effectively maintain your brakes:

1. Regular Inspection: Perform visual inspections of your brake components regularly, looking for signs of wear, damage, or any issues. This includes checking brake pads, rotors/discs, calipers, brake lines, and fluid reservoirs.

2. Brake Pad Check: Monitor the thickness of your brake pads. Most pads have a wear indicator groove; replace the pads if they are worn down to this level. Inspect the brake pads for uneven wear, which might indicate a caliper or rotor issue.

3. Brake Fluid: Check the brake fluid level in the reservoir regularly. Make sure the fluid is within the recommended range and is clean. Brake fluid absorbs moisture over time, leading to decreased performance, so consider changing it every 1-2 years.

4. Bleeding Brakes: Air can enter the brake lines, reducing braking effectiveness. Bleeding the brake system removes air bubbles and ensures proper fluid circulation. If you're unsure how to do this, consult your motorcycle's service manual or a professional mechanic.

5. Rotor/Disc Inspection: Examine the brake discs/rotors for any scoring, warping, or unusual wear patterns. If you notice deep grooves, cracks, or a blue hue, consider replacing the rotors.

6. Caliper Maintenance: Ensure the calipers move freely and that the pistons retract fully after releasing the brake lever. Lubricate caliper sliding pins with appropriate lubricant if necessary.

7. Brake Lines: Inspect brake lines for any signs of damage, bulging, or leakage. Damaged brake lines can compromise brake performance. Replace them if you notice any issues.

8. Lubrication: Lubricate pivot points and moving parts as needed. Use brake-specific lubricants to avoid contaminating the brake pads or rotors.

9. Brake Lever Feel: Pay attention to the feel of the brake lever. If it feels spongy or requires excessive force to engage, there might be air in the brake lines or other issues.

10. Professional Service: If you're not confident in your maintenance skills, or if you notice any major issues, it's best to have your brakes inspected and serviced by a professional mechanic.

11. Ride Responsibly: Practice safe riding habits that minimize excessive use of the brakes, such as maintaining a safe following distance and anticipating stops.

12. Owner's Manual: Refer to your motorcycle's owner's manual for specific maintenance recommendations and intervals.

Remember that brake maintenance is not something to be taken lightly. Properly maintained brakes are essential for your safety and the safety of others on the road. If you're ever unsure about any aspect of brake maintenance, seek advice from experienced riders or professional mechanics.

Maintaining your motorcycle's Anti-Lock Braking System (ABS) is essential for ensuring its optimal performance and your safety on the road. While the ABS components themselves don't require specific maintenance, keeping the overall braking system in good condition is crucial. Here's how to maintain your motorcycle's ABS effectively:

1. Regular Brake System Inspection: Perform routine inspections of your motorcycle's entire brake system, including the ABS components. Look for signs of wear, damage, leaks, and any issues that might affect braking performance.

2. Visual Inspection of ABS Components: Examine the ABS sensors, wiring, and connections for any signs of damage or deterioration. Ensure that the sensors are clean and free from debris.

3. Maintain Brake Fluid: Brake fluid is critical for the proper functioning of ABS. Regularly check the brake fluid level in the reservoir and top it up if necessary. Also, consider changing the brake fluid according to the manufacturer's recommended schedule to prevent moisture buildup.

4. Check Brake Pads and Rotors: Monitor the condition of your brake pads and rotors. Worn brake pads can compromise braking performance, and worn rotors can lead to uneven braking and ABS issues.

5. Brake Fluid Flush and Bleeding: Over time, brake fluid can become contaminated and lose its effectiveness. Perform brake fluid flushes and bleeding as recommended by the manufacturer to maintain ABS performance and prevent brake fade.

6. Maintain Tires: Proper tire maintenance is essential for ABS to function optimally. Ensure your tires are properly inflated and have sufficient tread depth to maintain good traction and prevent skidding.

7. Ride Responsibly: Ride within your skill level and adhere to safe riding practices. Sudden and aggressive braking can put undue stress on the ABS, so be mindful of your braking inputs.

8. Professional Inspection and Service: If you notice any unusual behavior in your ABS or have concerns about its performance, have your motorcycle inspected by a qualified mechanic with experience in ABS systems.

9. Follow Manufacturer's Recommendations: Refer to your motorcycle's owner's manual for specific maintenance recommendations related to the ABS. Different motorcycle models might have varying maintenance intervals.

10. Keep the Motorcycle Clean: Regularly clean your motorcycle, including the ABS sensors and components, to prevent dirt, debris, and contaminants from affecting the system's performance.

11. Update Software: For motorcycles with advanced ABS systems that include electronic control units (ECUs), keep the software updated as recommended by the manufacturer to ensure optimal performance.

Remember that while you can perform visual inspections and basic maintenance tasks, some ABS-related tasks might require specialized tools and expertise. If you're unsure about any aspect of ABS maintenance, seek assistance from a professional mechanic or a dealership with experience in your motorcycle's ABS.

In the world of two-wheelers, the journey to mastery begins with understanding the intricacies of the braking system. As you embark on the quest for your perfect ride, remember that the quality of your bike's brakes directly impacts your safety and the overall riding experience. The art of selecting the proper bike lies in assessing factors such as ABS availability, brake types, disc size, and overall braking performance.

Whether you're a seasoned rider or a newcomer to the world of motorcycles, investing time in studying and appreciating the braking system is a non-negotiable step. A bike equipped with a well-engineered braking mechanism not only empowers you with control and confidence but also serves as your trusted companion on every journey. As you venture forth on two wheels, may your choice be a testament to your commitment to safety, precision, and the exhilarating freedom that the open road offers.