In the symphony of mechanical precision that powers our vehicles, the clutch system takes centre stage, orchestrating the dance between engine and transmission. This blog post embarks on a journey through the intricacies of various clutch systems, shedding light on their nuances, advantages, and the art of choosing the right one for different driving experiences.

Discover the heart of automotive and motorcycle engineering as we delve into the world of clutch systems. From the versatile wet multi-plate to the high-performance slipper clutch, this guide unlocks the secrets of manual control, offering insights into functionality, advantages, and suitability across different vehicles.

The Evolution of Clutch Systems: From Early Mechanisms to Cutting-Edge Innovations

The clutch system, a linchpin in the automotive world, has undergone a remarkable evolution since its inception. This detailed article explores the rich history, evolutionary milestones, and the current state of clutch technology, and offers insights into the promising future of this critical component.

Historical Foundations: The journey of the clutch system dates back to the earliest days of automobiles. In the late 19th century, as vehicles transitioned from steam-powered to internal combustion engines, rudimentary forms of clutches were employed to manage power transfer. Early designs included cone clutches and leather-faced cone clutches, providing the basic functionality needed for manual gear engagement.

Evolutionary Milestones:

1. Mechanical Advancements: The early 20th century witnessed the refinement of mechanical clutches, with innovations such as the introduction of multi-plate clutches for enhanced torque handling in heavy-duty vehicles.

2. Hydraulic Transitions: In the mid-20th century, the automotive industry embraced hydraulic clutch systems, providing a smoother and more consistent feel to drivers.

3. Automation and Semi-Automatic Transmissions: The latter half of the 20th century saw the rise of semi-automatic and automated manual transmissions, reducing the need for direct driver engagement with the clutch pedal.

Present State of Clutch Technology:

1. Advanced Friction Materials: Modern clutch systems leverage advanced friction materials, enhancing durability and performance.

2. Hydraulic Enhancements: Hydraulic clutches have evolved with improved designs, reducing maintenance and offering a more responsive feel.

3. Integration with Transmission Technology: Clutches are now intricately linked with transmission control systems, contributing to smoother gear changes and increased fuel efficiency.

Future Prospects:

1. Electrification Impact: With the rise of electric vehicles, the role of traditional clutches is diminishing. However, novel clutch systems may emerge to manage power distribution within electric drivetrains.

2. Smart and Adaptive Clutches: Future developments may include smart clutches that adapt to driving conditions, optimizing power transfer for efficiency and performance.

3. Integration with Autonomous Driving: Clutch systems might evolve to complement autonomous driving technologies, offering seamless transitions between manual and automated modes.

From humble beginnings to the forefront of technological innovation, the clutch system has played a pivotal role in shaping the driving experience. As we stand at the crossroads of electrification and automation, the future promises new chapters in the evolution of clutch systems, marking their continued relevance in the dynamic landscape of automotive engineering.

Explain the clutch system in an automobile

The clutch system in an automobile is a critical component that facilitates the engagement and disengagement of the engine from the transmission. This mechanical system allows the driver to control the power flow between the engine and the wheels, enabling smooth gear changes and vehicle operation.

The primary components of a typical automotive clutch system include the clutch pedal, clutch disc, pressure plate, flywheel, and release bearing. Here's an overview of how the clutch system functions:

1. Clutch Pedal:

· The clutch pedal is located in the driver's compartment and is manually operated by the driver's foot.

· When the driver presses the clutch pedal, it disengages the clutch, interrupting the power transfer between the engine and the transmission.

2. Clutch Disc:

· The clutch disc is located between the engine's flywheel and the transmission input shaft.

· It has friction linings on both sides and is connected to the engine and transmission.

3. Pressure Plate:

· The pressure plate is bolted to the flywheel and exerts pressure on the clutch disc, holding it against the flywheel.

· When the clutch pedal is depressed, the pressure plate releases the clutch disc, allowing it to rotate freely.

4. Flywheel:

· The flywheel is attached to the engine's crankshaft and provides a smooth surface for the clutch disc and pressure plate to engage.

· It stores rotational energy and helps maintain a consistent engine speed.

5. Release Bearing:

· The release bearing, also known as the throw-out bearing, is positioned between the pressure plate and the clutch fork.

· When the clutch pedal is pressed, the release bearing disengages the pressure plate, allowing the clutch disc to rotate freely.

Functioning of the Clutch System:

· When the driver presses the clutch pedal, the pressure on the clutch disc is released.

· This disengages the engine from the transmission, enabling the driver to change gears or come to a complete stop without stalling the engine.

· Releasing the clutch pedal gradually re-engages the clutch, allowing power to be transmitted from the engine to the wheels.

how does the clutch system work

The clutch system plays a crucial role in the manual transmission of an automobile, providing the driver with control over the power transfer and enabling smooth gear changes for efficient and safe driving. Understanding the operation of the clutch system is fundamental for drivers who operate vehicles with manual transmissions.

allowing the driver to control the connection between the engine and the transmission. Here is a step-by-step explanation of how the clutch system works:

1. Engagement:

· When the engine is running, the crankshaft turns the flywheel, which is attached to it. The flywheel, in turn, is connected to the clutch plate or disc.

2. Clutch Pedal Pressed:

· When the driver presses the clutch pedal inside the vehicle, it activates a linkage system that disengages the clutch. The linkage typically involves a cable or hydraulic mechanism.

3. Release Bearing Activation:

· As the clutch is disengaged, the release bearing (or throw-out bearing) is pushed against the pressure plate. The pressure plate is a part of the clutch assembly and is connected to the flywheel.

4. Pressure Plate Disengagement:

· The release bearing, acting on the pressure plate, causes the pressure plate to move away from the clutch disc. The pressure plate initially presses the clutch disc against the flywheel, creating a connection between the engine and the transmission.

5. Clutch Disc Disengagement:

· With the pressure plate moved away, the clutch disc is now free to rotate independently. This disconnection interrupts the power transfer from the engine to the transmission.

6. Neutral State:

· At this point, the engine is still running, but it is effectively disconnected from the transmission. The vehicle is in a neutral state, and the driver can change gears without affecting the engine.

7. Gear Change or Idling:

· The driver can now shift gears by moving the gear lever to the desired position. When the clutch pedal is released gradually, the pressure plate comes back into contact with the clutch disc, re-establishing the connection between the engine and the transmission.

8. Power Transfer:

· As the clutch engages, power from the engine is once again transmitted through the clutch assembly to the transmission and, ultimately, to the wheels.

The clutch system's primary function is to temporarily disconnect the engine from the transmission, allowing the driver to change gears or keep the vehicle stationary while the engine is running. The driver's control over the clutch pedal dictates the engagement and disengagement of the clutch, influencing the vehicle's overall performance and drivability in a manual transmission system.

Mastering the Art of Clutch Systems in Automobiles and Motorcycles

In the realm of automobiles and motorcycles, the clutch system stands as a vital component, serving as the bridge between the engine and the transmission. This mechanical marvel allows for seamless gear changes, controlled acceleration, and the thrill of manual driving. In this exploration, we delve into the intricacies of various clutch systems, understanding their functionality, advantages, and suitability across different vehicles.

Understanding the Basics:

1. Wet Multi-Plate Clutch:

Advantages:

· Effective Cooling

· Durability

· Smooth Engagement

Disadvantages:

· Complexity

· Maintenance

Suitability:

· Versatile, found in a range of motorcycles offering a balance of performance and durability.

2. Dry Single-Plate Clutch:

Advantages:

· Simplicity

· Lightweight

· Ease of Maintenance

Disadvantages:

· Heat Generation

· Wear

Suitability:

· Common in smaller motorcycles, where simplicity and cost-effectiveness are priorities.

3. Slipper Clutch:

Advantages:

· Prevents Wheel Lockup

· Stability

· Smooth Transitions

Disadvantages:

· Complexity

· Cost

Suitability:

· Embraced by high-performance motorcycles, designed for aggressive riding and racing.

4. Hydraulic Clutch:

Advantages:

· Consistent Feel

· Reduced Effort

· Low Maintenance

Disadvantages:

· Complexity

· Potential Fluid Leaks

Suitability:

· Common in various motorcycles, especially those designed for comfort and ease of use.

5. Centrifugal Clutch:

Advantages:

· Automatic Engagement

· User-Friendly

· Simple Design

Disadvantages:

· Limited Performance

· Lack of Manual Control

Suitability:

· Found in scooters, mopeds, and small motorcycles where simplicity and ease of use are prioritized.

6. Sliding Clutch (Dog Clutch):

Advantages:

· Quick Gear Changes

· High Performance

· Direct Engagement

Disadvantages:

· Skill-Dependent

· Harsh Engagement

Suitability:

· Primarily used in racing motorcycles and high-performance bikes where quick and precise gear changes are critical.

Choosing the Right System:

Selecting the ideal clutch system involves a careful consideration of factors such as the vehicle's intended use, performance requirements, and the driver or rider's preferences. Wet multi-plate clutches offer versatility, while slipper clutches enhance performance during aggressive riding. Simpler designs like dry single-plate and centrifugal clutches find their place in commuter vehicles, ensuring ease of use.

Looking Ahead:

As technology evolves, the automotive landscape continues to witness innovations in clutch systems. Advancements aim to enhance efficiency, reduce maintenance requirements, and cater to the diverse needs of drivers and riders. Whether it's the roar of a high-performance motorcycle on the racetrack or the smooth transition between gears in a daily commuter, the clutch system remains a cornerstone of the driving experience.

Understanding the nuances of different clutch systems empowers enthusiasts and drivers alike to appreciate the engineering marvels that enable manual control and dynamic driving experiences. From the simplicity of centrifugal clutches to the precision of slipper clutches, each system contributes to the unique character of the vehicles we love to drive and ride. Mastering the art of clutch systems is, indeed, a journey through the heart of automotive and motorcycle engineering.

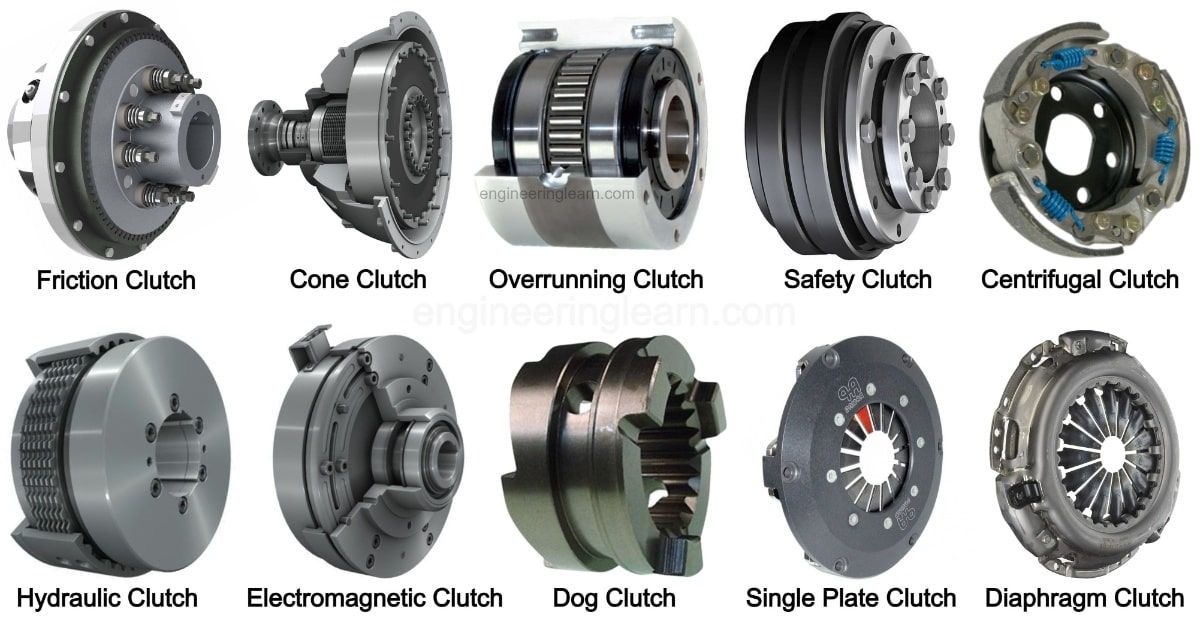

Types of Clutch Systems

There are several types of clutch systems used in vehicles, each designed to suit specific applications and driving conditions. The two main categories of clutches are mechanical clutches and hydraulic clutches. Within these categories, there are various subtypes. Here is an overview of different types of clutch systems:

Mechanical Clutches:

1. Friction Clutch:

· Single Plate Clutch: This is the most common type of friction clutch. It consists of a single clutch plate sandwiched between the flywheel and pressure plate.

· Multi-Plate Clutch: Uses multiple clutch plates interleaved with flywheel and pressure plate. It provides higher torque capacity in a compact design.

2. Cone Clutch:

· Utilizes conical surfaces for engagement and disengagement. As the cone moves, it causes the friction surfaces to come into contact or separate.

3. Centrifugal Clutch:

· Engages and disengages automatically based on engine speed. It uses centrifugal force to operate the clutch, making it suitable for certain types of small vehicles and machinery.

Hydraulic Clutches:

1. Hydraulic Release Bearings:

· Instead of a mechanical linkage, hydraulic release bearings use hydraulic pressure to engage and disengage the clutch. This design can provide smoother operation and reduced pedal effort.

2. Hydraulic Multi-Plate Clutch:

· Similar to the mechanical multi-plate clutch but utilizes hydraulic pressure for actuation. Often found in high-performance vehicles with automated manual transmissions.

Electromagnetic Clutches:

1. Electromagnetic Clutch:

· Engages and disengages based on an electromagnetic field. Commonly used in air conditioning compressors, engine cooling fans, and other auxiliary systems.

Semi-Automatic and Automated Manual Clutches:

1. Semi-Automatic Clutch:

· Also known as an automated manual transmission (AMT), it combines a manual gearbox with an automatic clutch. The driver can manually shift gears or allow the system to shift automatically.

2. Dual-Clutch Transmission (DCT):

· Uses two separate clutches for odd and even gears, allowing for quick and smooth gear changes. Commonly found in high-performance and some mainstream vehicles.

Other Specialized Clutches:

1. Dog Clutch:

· Commonly used in racing vehicles and motorcycles, it has toothed gears that engage and disengage with a sliding action.

2. Fluid Coupling:

· While not a traditional clutch, it's worth mentioning. It uses a fluid-filled chamber to transmit power, offering smooth engagement and torque multiplication.

3. Torque Converter:

· Commonly found in automatic transmissions, it uses a fluid coupling to transmit torque, allowing the vehicle to come to a complete stop without stalling the engine.

These various types of clutches cater to different vehicle designs, performance requirements, and transmission systems. The choice of a clutch system depends on factors such as vehicle type, intended use, and desired performance characteristics.

The suitability of different types of clutch systems depends on various factors, including the vehicle's design, intended use, performance requirements, and driver preferences. Here's a breakdown of the types of clutch systems and the vehicles they are best suited for:

Mechanical Clutches:

1. Friction Clutch:

· Single Plate Clutch: Commonly used in passenger cars and light-duty vehicles with manual transmissions.

· Multi-Plate Clutch: Found in performance-oriented and high-torque applications, such as sports cars and some heavy-duty trucks.

2. Cone Clutch:

· Historically used in some early vehicles and machinery; however, it has been largely replaced by other clutch types due to limitations in torque capacity and smooth engagement.

3. Centrifugal Clutch:

· Commonly found in small engine applications, such as go-karts, scooters, and some lawnmowers.

Hydraulic Clutches:

1. Hydraulic Release Bearings:

· Used in various vehicles, particularly in applications where smoother engagement and reduced pedal effort are desired. Can be found in both passenger cars and commercial vehicles.

2. Hydraulic Multi-Plate Clutch:

· Typically used in high-performance and sports cars with automated manual transmissions or dual-clutch transmissions.

Electromagnetic Clutches:

1. Electromagnetic Clutch:

· Found in various applications, including air conditioning compressors, engine cooling fans, and other auxiliary systems in vehicles and industrial machinery.

Semi-Automatic and Automated Manual Clutches:

1. Semi-Automatic Clutch:

· Common in a range of vehicles, including compact cars and some commercial vehicles. Offers a compromise between manual and automatic transmissions.

2. Dual-Clutch Transmission (DCT):

· Found in a variety of vehicles, from compact cars to high-performance sports cars. Known for providing quick and smooth gear changes.

Other Specialized Clutches:

1. Dog Clutch:

· Common in racing vehicles, motorcycles, and some high-performance sports cars, providing fast and precise gear changes.

2. Fluid Coupling and Torque Converter:

· Commonly used in automatic transmissions, making them suitable for a wide range of vehicles, including sedans, SUVs, and trucks.

It's important to note that advancements in automotive technology continue to influence the choice of clutch systems in modern vehicles. Additionally, factors such as fuel efficiency, driving comfort, and overall vehicle performance also play a role in determining the most suitable type of clutch for a particular application. Manufacturers select clutch systems based on a combination of these factors to provide an optimal driving experience for the intended vehicle.

Motorcycles typically use a variety of clutch systems, and the specific type depends on the motorcycle's design, intended use, and transmission configuration. Here are the common types of clutch systems used in motorcycles:

1. Wet Multi-Plate Clutch:

· This is the most common type of clutch used in motorcycles. It consists of multiple friction plates immersed in oil, which helps with cooling and reduces wear. The plates are alternately driven by the engine and connected to the transmission, and the clutch lever on the handlebar controls the engagement and disengagement of the clutch.

2. Dry Single-Plate Clutch:

· Some motorcycles, particularly smaller displacement bikes, use a dry single-plate clutch. It operates similarly to a wet multi-plate clutch but without the oil bath. Dry clutches are simpler but may be prone to more wear and generate more heat.

3. Slipper Clutch:

· Commonly found in high-performance and sport motorcycles, a slipper clutch helps prevent rear-wheel lockup during aggressive downshifting. It automatically slips or partially disengages when there is a significant difference in speed between the engine and the rear wheel.

4. Hydraulic Clutch:

· Many modern motorcycles, especially those in the sport and cruiser categories, use hydraulic clutches. A hydraulic system replaces the traditional cable-operated mechanism, providing a smoother and more consistent feel at the clutch lever.

5. Centrifugal Clutch:

· Some smaller motorcycles, scooters, and mopeds use a centrifugal clutch. It engages automatically as the engine speed increases, making it suitable for simple and user-friendly designs often found in commuter and entry-level bikes.

6. Sliding Clutch (Dog Clutch):

· In some high-performance motorcycles, especially those used in racing, a sliding clutch or dog clutch might be employed. It allows for quick and precise gear changes without the need for a traditional gear synchronization mechanism.

The choice of clutch system for a motorcycle depends on factors such as the bike's intended use, performance characteristics, and the manufacturer's design preferences. Motorcycles designed for sport and performance often feature advanced clutch systems to enhance overall performance and rider control, while commuter bikes may have simpler and more cost-effective clutch configurations.

Let's compare the mentioned clutch systems—wet multi-plate clutch, dry single-plate clutch, slipper clutch, hydraulic clutch, centrifugal clutch, and sliding clutch (dog clutch)—based on their advantages, disadvantages, and suitability of use:

Wet Multi-Plate Clutch:

Advantages:

1. Cooling: The oil bath provides effective cooling, reducing heat generated during operation.

2. Durability: The design distributes wear evenly across multiple plates, increasing the overall lifespan.

3. Smooth Engagement: Offers smooth engagement and disengagement, providing a comfortable ride.

Disadvantages:

1. Complexity: More components and complexity compared to some other clutch types.

2. Maintenance: Requires periodic oil changes, adding to maintenance requirements.

Suitability of Use:

· Commonly used in a wide range of motorcycles, including sport bikes, cruisers, and touring bikes, providing a good balance of performance and durability.

Dry Single-Plate Clutch:

Advantages:

1. Simplicity: Simpler design with fewer components, reducing manufacturing and maintenance costs.

2. Lightweight: Generally lighter than wet clutches, contributing to overall weight savings.

3. Ease of Maintenance: No need for an oil bath, making maintenance simpler.

Disadvantages:

1. Heat Generation: Tends to generate more heat during operation compared to wet clutches.

2. Wear: Wear may be uneven across the clutch plate.

Suitability of Use:

· Found in smaller displacement motorcycles and entry-level bikes where simplicity and cost-effectiveness are priorities.

Slipper Clutch:

Advantages:

1. Prevents Wheel Lockup: Reduces the risk of rear-wheel lockup during aggressive downshifting.

2. Stability: Enhances stability and control during rapid deceleration.

3. Smooth Transitions: Allows for smoother and faster gear changes.

Disadvantages:

1. Complexity: Adds complexity to the clutch system.

2. Cost: Typically more expensive compared to traditional clutches.

Suitability of Use:

· Primarily used in high-performance motorcycles, especially those designed for aggressive riding and racing.

Hydraulic Clutch:

Advantages:

1. Consistent Feel: Provides a consistent and smooth feel at the clutch lever.

2. Reduced Effort: Generally requires less effort at the clutch lever compared to cable-operated systems.

3. Low Maintenance: Hydraulic systems often require less maintenance than cable systems.

Disadvantages:

1. Complexity: Hydraulic systems can be more complex to repair than cable-operated systems.

2. Potential Fluid Leaks: The possibility of hydraulic fluid leaks, though rare, is a consideration.

Suitability of Use:

· Commonly found in various types of motorcycles, especially those designed for comfort and ease of use.

Centrifugal Clutch:

Advantages:

1. Automatic Engagement: Engages automatically with increasing engine speed, simplifying operation.

2. User-Friendly: Easy to use, making it suitable for beginners and commuter bikes.

3. Simple Design: Fewer components, leading to a simpler overall design.

Disadvantages:

1. Limited Performance: This may not be suitable for high-performance or sport-oriented motorcycles.

2. Lack of Manual Control: This does not allow for manual disengagement, limiting control.

Suitability of Use:

· Found in scooters, mopeds, and small motorcycles where simplicity and ease of use are prioritized.

Sliding Clutch (Dog Clutch):

Advantages:

1. Quick Gear Changes: Allows for fast and precise gear changes without synchronization.

2. High Performance: Suitable for high-performance motorcycles and racing applications.

3. Direct Engagement: Provides direct and immediate engagement of gears.

Disadvantages:

1. Skill-Dependent: Requires skilful and precise operation by the rider.

2. Harsh Engagement: This can result in harsh engagement if not operated correctly.

Suitability of Use:

· Primarily used in racing motorcycles and high-performance bikes where quick and precise gear changes are critical.

The choice of clutch system depends on the motorcycle's intended use, performance requirements, and the rider's preferences. Wet multi-plate clutches are versatile and common, while specific applications like racing might benefit from slipper clutches or sliding clutches. Simpler designs like dry single-plate and centrifugal clutches are suitable for smaller bikes and commuter vehicles, and hydraulic clutches offer a balance between ease of use and performance.

Maintaining the clutch in good working condition is essential for the smooth operation and longevity of your vehicle. Here are some tips to help you keep the clutch in optimal shape:

1. Avoid Riding the Clutch:

· Minimize the time spent with the clutch pedal partially engaged. Full engagement or disengagement reduces friction and heat, promoting longevity.

2. Proper Shifting Technique:

· Shift gears smoothly and avoid forceful or abrupt shifts. Rev matching during downshifts helps reduce stress on the clutch.

3. Avoid Slipping:

· Minimize unnecessary clutch slipping, especially during acceleration. Excessive slipping generates heat and wears down the clutch.

4. Complete Stops:

· Come to a complete stop before shifting between gears. Shifting without stopping can cause premature wear on the clutch components.

5. Proper Use of the Clutch Pedal:

· Don't rest your foot on the clutch pedal while driving. This can cause the clutch to engage slightly, leading to unnecessary wear.

6. Gradual Engagement:

· When releasing the clutch pedal, do so gradually. Smooth and gradual engagement helps prevent sudden stress on the clutch components.

7. Avoid "Riding" the Clutch on Hills:

· When stopped on an incline, use the handbrake to prevent rolling backwards. Avoid using the clutch alone to hold the vehicle on a hill.

8. Regular Inspections:

· Periodically inspect the clutch pedal for any unusual play, resistance, or vibrations. Address any issues promptly to prevent further damage.

9. Check Hydraulic System:

· If your vehicle has a hydraulic clutch system, check for leaks in the master cylinder or slave cylinder. Maintain proper fluid levels and replace fluids as recommended.

10. Clutch Adjustment:

· If your vehicle has a manual clutch cable, ensure it is properly adjusted according to the manufacturer's specifications.

11. Use the Right Gear:

· Ensure you are in the correct gear for the driving conditions. Being in too high a gear can lead to excessive slipping and premature wear.

12. Avoid Aggressive Driving:

· Aggressive driving, such as quick starts and sudden stops, can put unnecessary stress on the clutch. Drive smoothly and responsibly.

13. Regular Maintenance:

· Follow the manufacturer's recommended maintenance schedule. This may include periodic inspections and adjustments.

14. Professional Inspection:

· If you notice any unusual noises, smells, or behaviours related to the clutch, seek professional inspection and repairs promptly.

15. Select Quality Replacement Parts:

· When replacing clutch components, use high-quality, manufacturer-recommended parts to ensure proper fit and function.

By following these tips and adopting good driving habits, you can extend the life of your clutch system and minimize the need for premature repairs or replacements. Regular maintenance and careful driving contribute significantly to the overall health of the clutch in your vehicle.

Maintaining the clutch system is crucial for optimal performance and longevity of your vehicle. Here are some clutch maintenance tips to ensure smooth operation:

1. Regular Inspection:

· Periodically inspect the clutch components for wear, such as the clutch disc, pressure plate, and release bearing. Look for signs of damage, contamination, or uneven wear.

2. Check Fluid Levels:

· If your vehicle has a hydraulic clutch system, check the clutch fluid reservoir regularly. Ensure the fluid level is within the recommended range and top up if necessary with the manufacturer-recommended fluid.

3. Fluid Replacement:

· Follow the manufacturer's recommended schedule for clutch fluid replacement. Old or contaminated fluid can lead to poor clutch performance.

4. Inspect Hydraulic Lines:

· Examine the hydraulic lines for signs of leaks or damage. Address any issues promptly to prevent air from entering the hydraulic system, which can result in a spongy clutch pedal.

5. Adjustment Checks:

· If your vehicle has a manual clutch cable, check for proper adjustment according to the manufacturer's specifications. An improperly adjusted clutch can lead to premature wear.

6. Smooth Driving Habits:

· Adopt smooth driving habits. Avoid aggressive driving, quick starts, and abrupt stops, as these behaviours can put unnecessary stress on the clutch components.

7. Proper Shifting Technique:

· Shift gears smoothly, and practice rev matching during downshifts to reduce stress on the clutch. Avoid riding the clutch unnecessarily.

8. Avoid Slipping:

· Minimize unnecessary clutch slipping during acceleration, as excessive slipping can lead to overheating and premature wear.

9. Complete Stops:

· Come to a complete stop before shifting gears. Shifting without stopping can contribute to premature wear on the clutch.

10. Avoid Hill Holding with Clutch Alone:

· When stopped on an incline, use the handbrake to prevent rolling backwards. Avoid using the clutch alone to hold the vehicle on a hill.

11. Temperature Considerations:

· Be mindful of driving conditions that can increase clutch temperature, such as heavy traffic or towing. Excessive heat can accelerate wear.

12. Quality Replacement Parts:

· When replacing clutch components, use high-quality, manufacturer-recommended parts. This ensures proper fit and function, contributing to the overall health of the clutch system.

13. Professional Inspection:

· If you notice any unusual noises, vibrations, or changes in the clutch pedal feel, seek professional inspection and address any issues promptly.

14. Follow Maintenance Schedule:

· Adhere to the manufacturer's recommended maintenance schedule for your vehicle. This includes regular inspections and adjustments as specified in the owner's manual.

15. Avoid Excessive Idling:

· Prolonged idling with the clutch engaged can lead to increased heat and wear. Avoid unnecessary idling when possible.

16. Appropriate Gear Selection:

· Ensure you are in the correct gear for the driving conditions. Using the right gear reduces stress on the clutch.

By incorporating these clutch maintenance tips into your routine, you can contribute to the optimal performance and longevity of the clutch system in your vehicle. Regular inspections, proper driving habits, and timely repairs or adjustments are key to keeping the clutch in top condition.

As the automotive landscape continues to evolve, the clutch system remains a crucial player in delivering dynamic and controlled driving experiences. Whether you're navigating the city streets or pushing the limits on the racetrack, understanding the diverse clutch systems enhances your appreciation for the engineering marvels that power our beloved vehicles.

#ClutchSystems #AutomotiveEngineering #MotorcycleTech #ManualDriving #EngineeringMarvels #VehiclePerformance #GearShifting #DrivingExperience #GoodOldBandit #Gud Ol Bandit #SanjayMohindroo